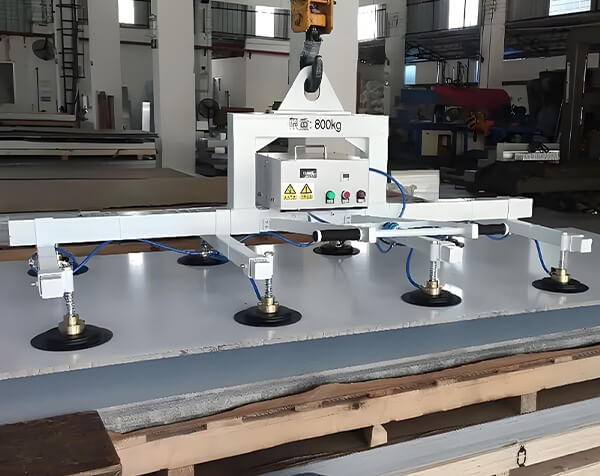

Choosing the right vacuum lifter or vacuum handling equipment is critical for safe and efficient material handling. The selection process must be driven by the characteristics of the material you need to lift, including its size, texture, and weight. These factors directly determine the optimal type and material of the suction cup required.

The material texture of the workpiece is the primary factor in suction cup selection:

Beyond material texture, the operating environment also plays a role. Factors like ambient temperature, humidity, and the temperature of the material itself can influence the performance and required durability of the suction cup material.

Regular maintenance is key to maximizing the lifespan of your lifting equipment. The most common components that require inspection and eventual replacement are:

It is highly recommended to source replacement parts, especially for the vacuum pump and suction cups, from the original equipment manufacturer (OEM) to ensure perfect compatibility and performance. Regular inspection and timely maintenance of these two components can significantly extend the overall service life of your vacuum lifter.

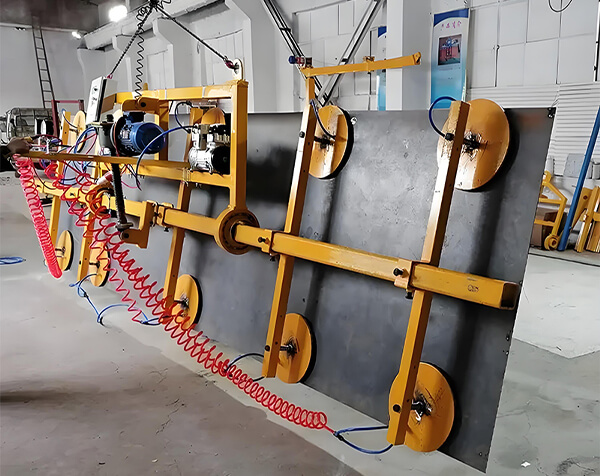

Specialized Curtain Wall Glass Suction Lifters are designed to meet the rigorous demands of façade installation:

By carefully considering the material specifications and leveraging the advanced features of modern vacuum lifters, you can ensure the safest and most efficient handling of delicate and heavy loads.

Originally prevalent in port construction for their efficiency, grab cranes now play an increasingly vital role in urban rail transit projects. The growing demands of metro construction have elevated both technical specifications and economic considerations for muck removal equipment.

In modern industrial production, different industries have unique requirements for lifting equipment. KBK light cranes have demonstrated exceptional performance across numerous sectors, thanks to their specialized capabilities.

Industrial lifting operations commonly utilize both single-girder and double-girder cranes, but their structural differences lead to distinct performance characteristics.