A hysteresis cable reel is a specialized power supply device used for large mobile lifting equipment traveling on rails. It is widely applied in portal cranes, container cranes, and other heavy machinery in ports.

Compared to counterweight or torque motor reels, hysteresis reels offer:

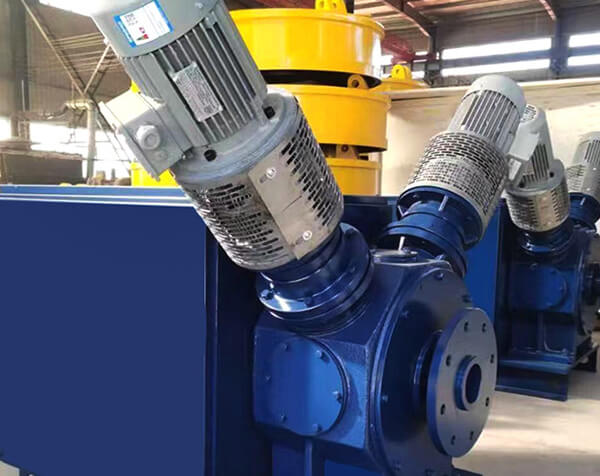

Internal Components: The system consists of the cable drum, planetary gears, conical gearbox, collector (slip ring), hysteresis coupling, and an electric motor.

How the Hysteresis Coupling Works: The coupling consists of multiple permanent magnets creating a multi-pole field and an induction disk. When the motor drives the induction disk at high speeds, magnetic coupling rotates the disk. Any speed difference (slip) creates a torque that resists the slip. This non-contact magnetic connection allows for smooth driving or braking.

Since these reels work in high temperature, humidity, and salt spray environments:

Verify that cable connections are tight and free of corrosion.

Regularly lubricate gearboxes and planetary gears.

Check the slip ring and carbon brushes to ensure they are clean, dry, and making good contact.

Originally prevalent in port construction for their efficiency, grab cranes now play an increasingly vital role in urban rail transit projects. The growing demands of metro construction have elevated both technical specifications and economic considerations for muck removal equipment.

In modern industrial production, different industries have unique requirements for lifting equipment. KBK light cranes have demonstrated exceptional performance across numerous sectors, thanks to their specialized capabilities.

Industrial lifting operations commonly utilize both single-girder and double-girder cranes, but their structural differences lead to distinct performance characteristics.