Common Scrap Grab Varieties

Scrap grabs mainly fall into three categories based on design: multi-tooth grabs (2+3, 3+4 configurations), clamshell grabs, and multi-jaw (petal) grabs. Each type serves specific material handling purposes in different working conditions.

Multi-Tooth Grabs (2+3, 3+4 Configurations)

These scrap grabs feature interlocking teeth arrangements ideal for handling long, neatly stacked scrap metals. Their structural design makes them particularly suitable for steel mills and manufacturing plants where workers need to move organized bundles of scrap metal efficiently.

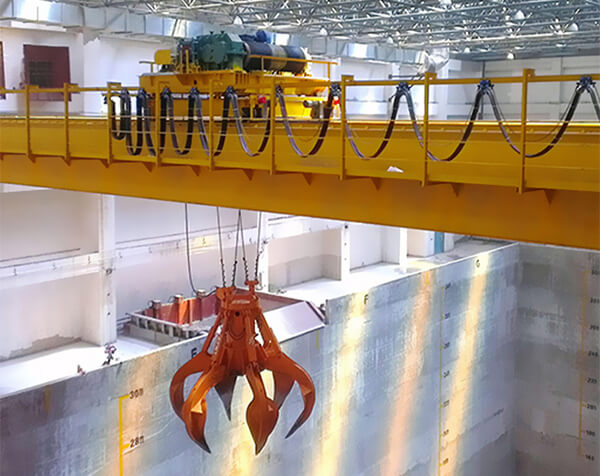

Multi-Jaw (Petal) Grabs

With four or five movable petal, these scrap grabs excel at collecting scattered or irregularly shaped metal waste. Various industries rely on their versatility for handling mixed or disordered scrap materials that require flexible grasping capability.

Multi-Jaw (Petal) Grabs

Steel processing plants frequently use clamshell-style grabs for loading fragmented scrap. The enclosed design proves especially effective when handling small cut-offs and shredded materials generated during metal fabrication processes.

Salvage lifting electromagnet. Its excitation mode can be: constant voltage mode, strong excitation mode and overexcitation mode. The products have different pertinences. Please refer to the selection guide to choose the one suitable for underwater handling of cast iron ingots, steel balls and various scrap steel.

Grab cranes play a pivotal role in bulk material handling operations. Their lifting control systems prove crucial for optimizing efficiency and ensuring operational quality. Modern intelligent control technology has demonstrated remarkable value in improving grab crane performance.

The mobile jib crane is made of thin-walled profiles and special-shaped steel. This structure reduces the number of splicing welds in the structure and improves fatigue resistance. A variety of new high-strength low-alloy steel materials are used to improve the bearing capacity, improve the stress conditions, reduce the self-weight and increase the appearance of beauty.