Description

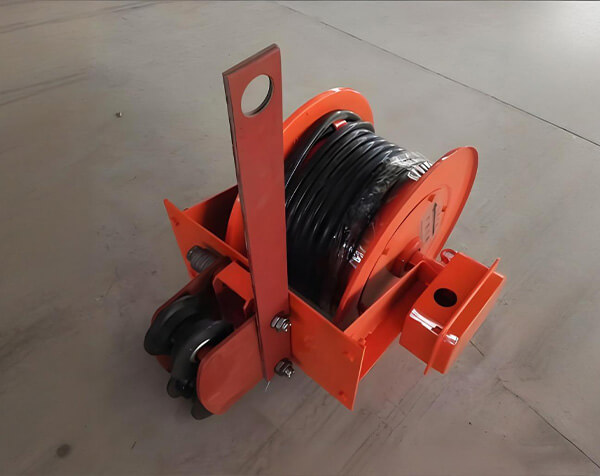

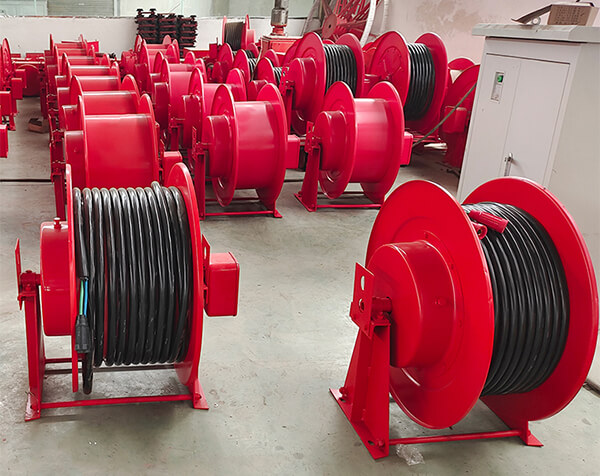

JT series cable reel is a mechanical device that introduces the internationally-used wind-up type cable reel technology, uses a volute spring as the power, and uses the energy of the spring to automatically rewind the cable.

A spring reel is a spring-driven device specifically designed for automatically winding power or signal cables. As the moving equipment (such as cranes or trolleys) moves, the cable is pulled out, while the spring winds around the mandrel, storing energy. When the equipment returns, the spring releases the energy, driving the reel to rotate in the opposite direction, thus achieving synchronous cable winding.

Features

Structural features of the spring reel:

1. Simplified structure, making debugging, installation, and maintenance very convenient.

2. Powered by the spring, with no electrical energy consumption, ensuring safety and reliability during operation.

3. Equipped with a reversible mechanism to effectively prevent spring breakage when the reel reverses.

4. Achieving smooth and continuous power transfer through the ingenious combination of a slip ring and a carbon brush holder. The flange of the spring reel is made of galvanized metal sheet, and the outer edge of the flange is rolled. The core of the reel is made of sheet metal, protected by an outer polyester coating, which effectively prevents corrosion.

I. Common Spring Materials

Common spring materials include ordinary carbon steel, alloy steel, stainless steel, copper, and copper alloys. Carbon steel is a common material with excellent elasticity and mechanical properties, widely used in spring cable reels. Stainless steel, on the other hand, has good corrosion resistance and a long service life, and is used in some special applications.

II. The Impact of Spring Material on Service Life

1. Springs on cable reels are subjected to different forces during use; therefore, selecting a suitable spring material ensures its strength and elasticity, resulting in a longer service life.

2. The quality of the spring material also affects the service life of the spring cable reel. Generally, elastic steel and alloy steel have a longer service life than carbon steel, while stainless steel also has a relatively long service life.

3. When selecting spring materials, their heat treatability and machinability should also be considered to ensure the quality of the spring cable reel.

Technical Data

|

Model |

Slip ring current Max(A) |

Cable Diameter (Max)mm |

Cable length |

Voltage (V) |

|

JDT-10 |

5A-20A |

15 |

9-11 |

24V-380V |

|

JDT-11 |

20A-80A |

25 |

10-25 |

110V-380V |

|

JDT-12 |

100A-200A |

30 |

20-35 |

24V-460V |

|

JDT-20 |

36 |

30-55 |

||

|

JDT-21 |

50-85 |

|||

|

JDT-22 |

150A-400A |

|||

|

JDT-30 |

40 |

80-110 |

||

|

JDT-31 |

120-150 |

Applications

It is suitable for various places that require mobile cable power supply, such as lifting electromagnets, electric flatbed carts, various cranes, hydraulic grabs, etc.

Service

2. Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

2. Replacement of damaged components (non-human-induced) is provided during the warranty period.

2. Safety and Compliance Support: Ensure that their products comply with local and international safety and regulatory standards, and provide relevant documentation and support.

2. We will send professional Chinese crane installation team or find local crane installation team according to the product plan and customer demand, to ensure that the product can be used safely and effectively.

-600x476.jpg)