Description

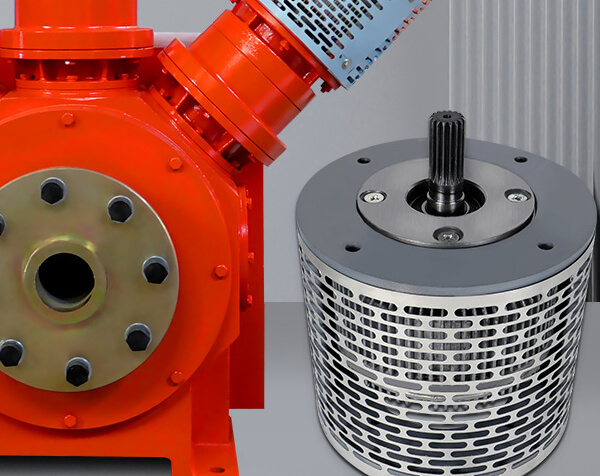

Hysteresis couplings and permanent magnet drive systems mainly consist of three parts: a copper rotor, a permanent magnet rotor, and a controller. Generally, the copper rotor is connected to the motor shaft, and the permanent magnet rotor is connected to the shaft of the driven machine. There is an air gap (called an air gap) between the copper rotor and the permanent magnet rotor; there is no mechanical connection for transmitting torque. This creates a soft (magnetic) connection between the motor and the driven machine. The torque and speed of the driven machine shaft are adjusted by regulating the air gap.

Features

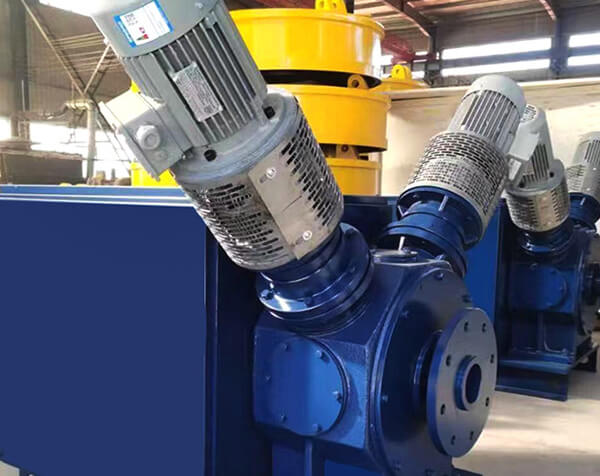

1. The hysteresis coupling is the core component inside the drum, consisting of a driving disc connected to the motor, a driven disc connected to the gear reducer, and a one-way clutch.

2. The coercivity of the permanent magnet material allows for effective torque transmission. When the motor drives the driving disc to rotate at high speed, the driven disc also rotates under the influence of magnetization, thus outputting a constant torque. Under overload conditions, the coupling will slip to protect the equipment. The number and spacing of the driving and driven discs can be flexibly configured according to the actual load characteristics to adjust the winding torque and cable stress.

Applications

Hysteresis couplings are primarily used in applications requiring precise torque control, smooth motion, and isolation. They transmit torque through the hysteresis effect, achieving contactless transmission, preventing leakage, and providing stable loading or braking effects. Examples include applications such as motor testing and precision tension control.

Service

2. Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

2. Replacement of damaged components (non-human-induced) is provided during the warranty period.

2. Safety and Compliance Support: Ensure that their products comply with local and international safety and regulatory standards, and provide relevant documentation and support.

2. We will send professional Chinese crane installation team or find local crane installation team according to the product plan and customer demand, to ensure that the product can be used safely and effectively.

-600x476.jpg)