Description

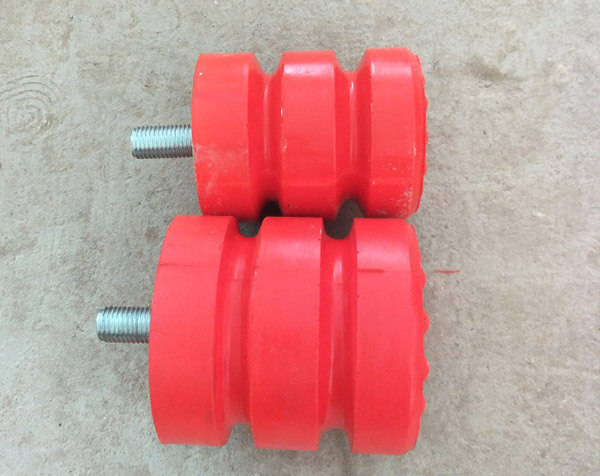

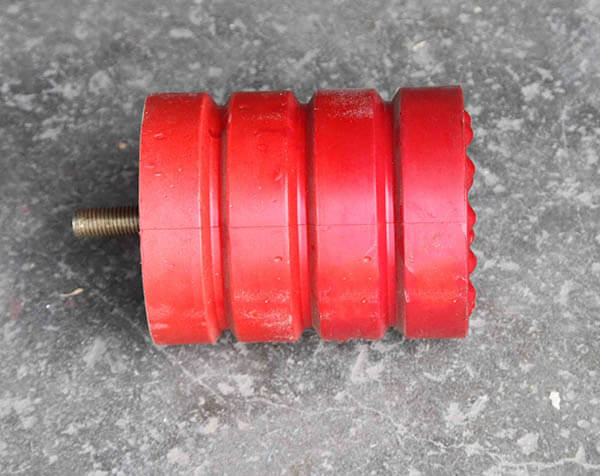

Crane buffers are important components used in lifting equipment to absorb impact energy and reduce collision force. They are usually installed at the end of the crane track or on the crane trolley to prevent collisions when running to the extreme position, thereby protecting the safety of the crane, buildings and personnel. Crane buffers are mainly divided into two categories: polyurethane buffers and composite buffers.

Features

1.Large energy absorption and good buffering performance.

40% of the energy can be consumed in the buffering process, 60% of the energy is stored and finally released, moderate rebound, good compressibility, good resilience.

2.Light weight

3.Low cost. Soft collision when working, no noise, no sparks, often used in explosion-proof places

Technical Data

| Item | Model | D mm | H mm | h mm | B mm | b mm | mm | Buffer capacity kn.m | cushion stroke mn | Cushioning force kn |

| 1 | JHQ-C-1 | 65 | 80 | 8 | 100 | 70 | 12 | 0.265 | 60 | 28 |

| 2 | JHO-C-2 | 80 | 80 | 8 | 115 | 85 | 12 | 0.400 | 60 | 42 |

| 3 | JHO-C-3 | 80 | 100 | 8 | 115 | 85 | 12 | 0.502 | 75 | 42 |

| 4 | JHO-C-4 | 100 | 80 | 8 | 130 | 100 | 14 | 0.628 | 60 | 66 |

| 5 | JHO-C-5 | 100 | 100 | 8 | 130 | 100 | 14 | 0.785 | 75 | 66 |

| 6 | JHO-C-6 | 100 | 125 | 8 | 130 | 100 | 14 | 0.980 | 94 | 66 |

| 7 | JHO-C- | 125 | 100 | 10 | 165 | 130 | 14 | 1.227 | 75 | 103 |

| 8 | JHO-C-8 | 125 | 125 | 10 | 165 | 130 | 14 | 1.533 | 94 | 103 |

| 9 | JHO-C-9 | 125 | 160 | 10 | 165 | 130 | 14 | 1.960 | 120 | 103 |

| 10 | ,IHO-C-10 | 160 | 125 | 10 | 200 | 160 | 18 | 2.512 | 94 | 169 |

| 11 | JHO-C-11 | 160 | 160 | 10 | 200 | 160 | 18 | 3.125 | 120 | 169 |

| 12 | JHO-C-12 | 160 | 200 | 10 | 200 | 160 | 18 | 4.019 | 150 | 169 |

| 13 | JHO-C-13 | 200 | 160 | 12 | 250 | 200 | 18 | 5.024 | 120 | 265 |

| 14 | JHO-C-14 | 200 | 200 | 12 | 250 | 200 | 18 | 6.280 | 150 | 265 |

| 15 | JHO-C-15 | 200 | 250 | 12 | 250 | 200 | 18 | 7.850 | 188 | 265 |

| 16 | JHO-C-16 | 250 | 200 | 12 | 320 | 250 | 22 | 9.810 | 150 | 414 |

| 17 | JHO-C-17 | 250 | 250 | 12 | 320 | 250 | 22 | 12.266 | 188 | 414 |

| 18 | JHO-C-18 | 250 | 320 | 12 | 320 | 250 | 22 | 15.700 | 240 | 414 |

| 19 | JHO-C-19 | 320 | 250 | 14 | 400 | 315 | 22 | 20.096 | 188 | 675 |

| 20 | JHO-C-20 | 320 | 320 | 14 | 400 | 315 | 22 | 25.732 | 240 | 675 |

| 21 | JHO-C-21 | 320 | 400 | 14 | 400 | 315 | 22 | 32.154 | 300 | 675 |

| 22 | JHO-C-22 | 320 | 450 | 14 | 400 | 315 | 22 | 36.17 | 337 | 675 |

| 23 | JHO-C-23 | 400 | 450 | 14 | 460 | 370 | 22 | 56.5 | 337 | 1054 |

| 24 | JHO-C-24 | 400 | 300 | 14 | 460 | 370 | 22 | 37.7 | 225 | 1054 |

Applications

Crane buffers are installed at the end of the conveyor belt to absorb impact energy, protect the belt from damage, and extend its service life. At the same time, hydraulic shock absorbers can also reduce noise and vibration, improving the comfort of the working environment.

Service

2. Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

2. Replacement of damaged components (non-human-induced) is provided during the warranty period.

2. Safety and Compliance Support: Ensure that their products comply with local and international safety and regulatory standards, and provide relevant documentation and support.

2. We will send professional Chinese crane installation team or find local crane installation team according to the product plan and customer demand, to ensure that the product can be used safely and effectively.

-600x476.jpg)