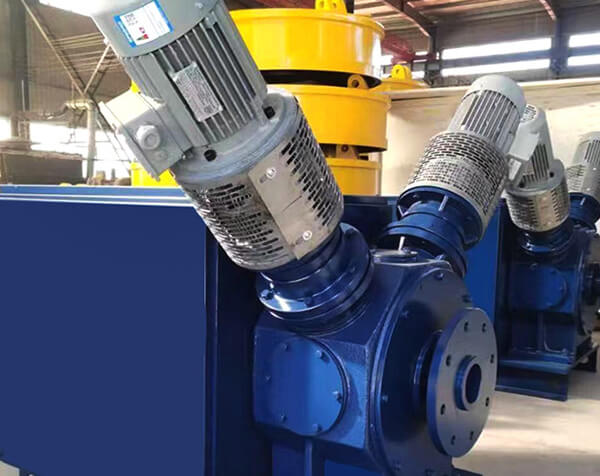

Description

The drum group is the primary component of the lifting machinery. The drum is used to wind the wire rope in the lifting mechanism to transmit power. The drum group consists of a drum, a drum group, a gear coupling, a bearing frame and other components. The drum shaft is connected to the reducer through a gear coupling. The drum used for the crane with the wire rope fixed on the drum is a compound drum. There are spiral grooves at both ends of the drum, and the spiral directions are opposite. The two ends of the wire rope are fixed on the outer ends of the left and right spiral grooves respectively. The wire rope is generally fixed on the drum with a pressure plate. This fixing method is simple and easy to disassemble. In order to ensure safety, reduce the pressure on the fixed pressure plate or the force on the chess piece, and ensure that the object-picking device is lowered to the extreme position, in addition to the fixed rope loop, at least 2 turns of wire rope should be left on the drum. These turns of wire rope are called safety loops, also called load-reducing loops. Generally, cast iron no lower than HT20-40, ZG25, ZG35 cast steel or Q235B, Q345B steel plates are selected for welding.

Features

1.Compact structure and space saving:

The modular design makes the drive, brake and gearbox of the drum compact, easy to install and maintain, and can effectively utilize the working space of the crane.

2.Strong and durable:

The drum manufactured by steel plate welding process has higher hardness, wear resistance and impact resistance, and longer service life.

3.High safety:

The drum is usually equipped with a second lifting brake to improve the safety of the lifting process.

4.Easy to maintain and repair:

The clear structural design is convenient for daily maintenance and repair work.

5.Extend the life of the wire rope:

The large diameter drum can increase the diameter ratio of the drum to the wire rope, thereby extending the service life of the wire rope.

Technical Data

| Item | A | B | C | D1 | D2 | d | E | F | Weight(kg) |

| 1 | 300 | 360 | 400 | 500 | 700 | 15 | 610 | 760 | 143 |

| 2 | 300 | 360 | 400 | 500 | 700 | 15 | 710 | 860 | 455 |

| 3 | 400 | 460 | 450 | 600 | 800 | 18 | 643 | 800 | 162 |

| 4 | 500 | 580 | 550 | 800 | 1000 | 18 | 835 | 990 | 236 |

Applications

It is widely used in various industrial sectors, including lifting machinery, conveying equipment, and oil rigs.

Service

2. Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

2. Replacement of damaged components (non-human-induced) is provided during the warranty period.

2. Safety and Compliance Support: Ensure that their products comply with local and international safety and regulatory standards, and provide relevant documentation and support.

2. We will send professional Chinese crane installation team or find local crane installation team according to the product plan and customer demand, to ensure that the product can be used safely and effectively.

-600x476.jpg)