Description

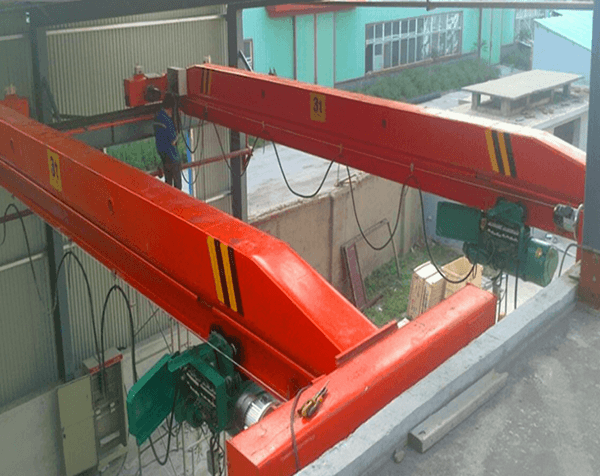

Single Beam End Beam For Bridge Crane is composed by Wheels, motors, buffers, collector base, girder joint plate and bolts, etc. The end beam adopts rectangular control, CNC boring and milling integrated customized machine tool, a one-time completion of opening, boring, drilling. Equipped with high quality reducer, hollow shaft drive, high working level, wide speed adjustment range, widely popular.

Features

1. Travel units with precisely manufactured wheels made of wear-resistant material provide for smooth running characteristics

2. Variable-speed inverter-fed drives for precise positioning and gentle loads on the entire design

3. Low maintenance costs: the travel units are rated for the entire crane service life

Our supported and suspended end carriages, standardized wheel heads and bogies are ideal for single-girder cranes, double-girder cranes, and other industrial applications.

Technical Data

|

End carriage model |

Application of crane model |

Rectangular steel tube |

Wheel size |

Motor power |

|

L125-20 |

1t-11.5m |

150*150*6 |

W125*60 |

0.3KW*2 |

|

L160-25 |

2t/3t-16.5m |

150*200*8 |

W160*70 |

0.4KW*2 |

|

L200-30 |

5t-22.5m |

150*250*8 |

W200*70 |

0.4KW*2 |

|

0.75KW*2 |

||||

|

L250-35A |

10t-28.5m |

200*250*8 |

W250*80 |

0.75KW*2 |

|

200*300*8 |

1.1KW*2 |

|||

|

1.5KW*2 |

||||

|

L315-30 |

20t-16.5m |

200*400*8 |

W315*90 |

1.5KW*2 |

Applications

Overhead Crane Moving End Beam Electric Motor Rail Traveling Beam

are widely used in industries such as metallurgy, transportation, railways, ports, etc

Service

2. Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

2. Replacement of damaged components (non-human-induced) is provided during the warranty period.

2. Safety and Compliance Support: Ensure that their products comply with local and international safety and regulatory standards, and provide relevant documentation and support.

2. We will send professional Chinese crane installation team or find local crane installation team according to the product plan and customer demand, to ensure that the product can be used safely and effectively.

-600x476.jpg)