- Capacity: 5~40t

- Span: 3~12m

- Lifting Height: 2-9

- Working Class: A3-A5

- Power Supply: 380V 50Hz or Customized

- Applications: construction site, ports, freight yards, factories and other fields

Description

Single beam tire gantry crane is the gantry crane that can move freely on highways and non hardened roads. It uses tires as support and driving structure, which can be quickly moved to the construction site for use. Tire crane is mainly composed of three parts: body, lifting machinery, and walking system.

Features

1.FEM design standard: Conduct finite element analysis during the design phase to ensure design safety and structural stress safety

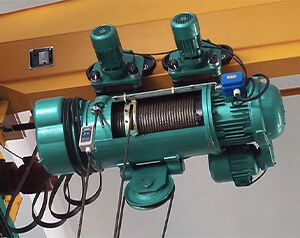

2. Electric hoist is used for the lifting mechanism: it is cheap and saves costs

3. Free walking: With multiple steering modes, it can be easily operated through the remote control or cab

4. Space saving: With a small turning radius, it can save the workspace required by the equipment

Technical Data

|

Model |

KE-5T |

KE-10T |

KE-20T |

KE-30T |

KE-40T |

|

Lifting Capacity |

5t |

10t |

20t |

30t |

40t |

|

Effective inner width(ODM) |

3100mm |

4000mm |

4000mm |

5000mm |

6000mm |

|

Lifting Height |

3000mm |

3000mm |

4000mm |

4000mm |

5000mm |

|

Power type |

diesel engine/cable/Battery |

||||

|

Walking device |

Hydraulic /Motor |

||||

|

Steering mode |

Diagonal Running/Straight Runing |

||||

|

Tires |

Solid tire |

||||

|

Lifting Tools |

Hook,Lifting beam, lifting magnet, permanent magnet |

||||

Options And Components

Applications

RTG cranes provide flexible, trackless lifting solutions for diverse heavy-duty industries. Key applications include:

Port & Container Yards: Efficient stacking and rapid handling of ISO containers.

Precast Concrete: Precise loading and moving of heavy bridge girders and concrete segments.

Steel & Logistics: Optimized material handling in large-scale steel stockyards and warehouses.

Infrastructure Projects: Reliable support for tunnel construction and large equipment assembly.

Our mobile gantry cranes ensure maximum maneuverability and productivity in any demanding workspace.

Service

2. Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

2. Replacement of damaged components (non-human-induced) is provided during the warranty period.

2. Safety and Compliance Support: Ensure that their products comply with local and international safety and regulatory standards, and provide relevant documentation and support.

2. We will send professional Chinese crane installation team or find local crane installation team according to the product plan and customer demand, to ensure that the product can be used safely and effectively.

-600x476.jpg)