Description

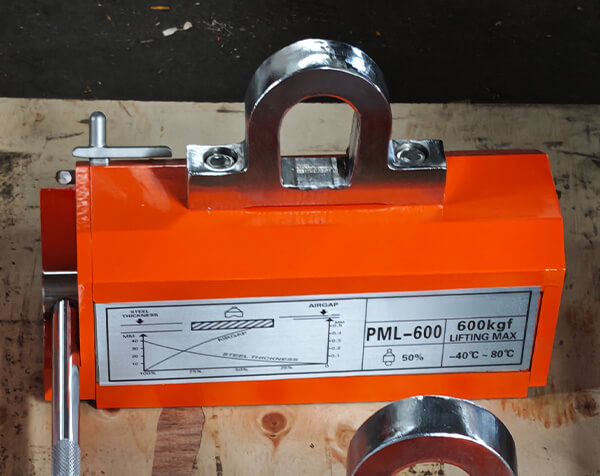

Manual permanent magnet chucks, as magnetic lifting tools, can lift different types of steel materials and plates without the need for electricity. Their structure utilizes the repulsion and attraction of magnetic poles, and the V-groove design at the bottom facilitates better gripping of workpieces and round steel. They are called permanent magnets because they use rare-earth neodymium magnets, which possess magnetism in all directions and are commonly used in many fields.

Features

Permanent magnet lifting plates are specifically manufactured using modern high-performance neodymium magnets (Nd-Fe-B Neodymium Magnets). This material is characterized by its lightweight nature, making it suitable for small-scale designs, while simultaneously generating powerful gripping force; it has a high safety factor, with a maximum pull-out force of 3.5 times the weight being lifted.

Technical Data

|

Model |

Rated capacity |

Pull-off force |

Length (mm) |

Width (mm) |

Height (mm) |

Net weight (kg) |

Gross weight (kg) |

|

PML-100 |

100 |

3.5 times |

87 |

64 |

69 |

3 |

3.5 |

|

PML-200 |

200 |

3.5 times |

142 |

87 |

85 |

7.1 |

7.6 |

|

PML-300 |

300 |

3 times |

143 |

89 |

87 |

7.8 |

8.3 |

|

PML-400 |

400 |

3 times |

178 |

89 |

87 |

9.5 |

11 |

|

PML-600 |

600 |

3 times |

200 |

112 |

103 |

16.1 |

18 |

|

PML-800 |

800 |

3 times |

222 |

111 |

116 |

20.5 |

23 |

|

PML-1000 |

1000 |

3 times |

267 |

133 |

126 |

32 |

34 |

|

PML-1500 |

1500 |

3 times |

295 |

143 |

143 |

43 |

45 |

|

PML-2000 |

2000 |

3 times |

355 |

155 |

155 |

59 |

63 |

|

PML-3000 |

3000 |

2.8 times |

410 |

160 |

180 |

82 |

86 |

|

PML-5000 |

5000 |

2.8 times |

508 |

234 |

196 |

180 |

188 |

|

PML-10T |

10000 |

2.8 times |

793 |

300 |

465 |

560 |

580 |

|

Model |

Rated lifting capacity |

Pull-off force |

Length(mm) |

Width(mm) |

Height(mm) |

Net weight (kg) |

Gross weight (kg) |

|

HD-100 |

100 |

3.5 times |

87 |

64 |

69 |

3.5 |

4 |

|

HD--200 |

200 |

3.5 times |

142 |

87 |

85 |

7.6 |

8.1 |

|

HD--300 |

300 |

3.5 times |

178 |

88 |

85 |

9.6 |

11 |

|

HD--400 |

400 |

3.5 times |

200 |

112 |

103 |

16 |

17 |

|

HD--600 |

600 |

3.5 times |

222 |

111 |

116 |

20.1 |

22 |

|

HD--800 |

800 |

3.5 times |

267 |

133 |

126 |

30 |

32 |

|

HD-1000 |

1000 |

3.5 times |

295 |

143 |

143 |

41 |

43 |

|

HD--1500 |

1500 |

3.5 times |

355 |

155 |

155 |

61 |

65 |

|

HD--2000 |

2000 |

3.3 times |

360 |

160 |

182 |

74 |

77 |

|

HD--3000 |

3000 |

3.3 times |

467 |

160 |

182 |

95 |

99 |

|

HD--5000 |

5000 |

3.3 times |

600 |

232 |

260 |

222 |

230 |

|

HD--10T |

10000 |

3.0 times |

600 |

467 |

260 |

580 |

600 |

Waterproof permanent magnetic lifter

|

Model |

Rated lifting capacity |

Pull-off force |

Length (mm) |

Width (mm) |

Height (mm) |

Handle length Long handle |

Net weight (kg) |

|

HG-150 |

150 |

4.0 |

180 |

81 |

70 |

200 |

6.5 |

|

HG-300 |

300 |

4.0 |

211 |

81 |

83 |

200 |

11 |

|

HG-600 |

600 |

4.0 |

288 |

112 |

106 |

250 |

22 |

|

HG-1000 |

1000 |

4.0 |

338 |

148 |

131 |

280 |

43 |

|

HG-2000 |

2000 |

4.0 |

425 |

160 |

160 |

360 |

90 |

Applications

Lifting electromagnets are widely used in various occasions. In industries such as steel, rail transit, and automobiles, lifting electromagnets can be used to automatically pick up and place various metal materials such as steel, alloy materials, steel plates, hollow shafts, etc. It can also be used for automatic collection of garbage, disposal of hazardous materials such as air and chemical media, or for rescue work in harsh environments such as high altitude. It can also be used in fields such as mechanical processing, loading and unloading, and handling.

Service

2. Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

2. Replacement of damaged components (non-human-induced) is provided during the warranty period.

2. Safety and Compliance Support: Ensure that their products comply with local and international safety and regulatory standards, and provide relevant documentation and support.

2. We will send professional Chinese crane installation team or find local crane installation team according to the product plan and customer demand, to ensure that the product can be used safely and effectively.

-600x476.jpg)